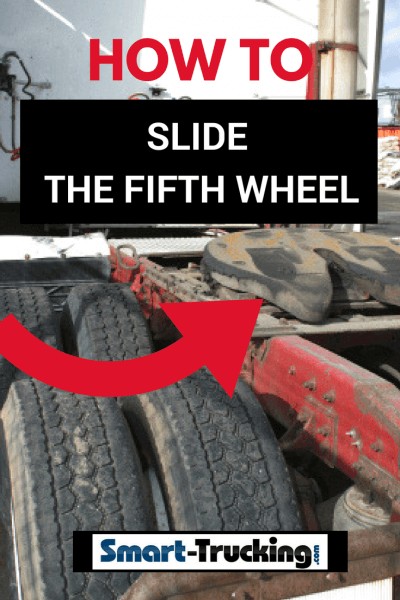

There are a few important steps involved in successfully moving the fifth wheel, in order to transfer weight from the drive axles to steering axle.

Professional drivers must be familiar with how to slide the fifth wheel on their truck. Otherwise, they can easily damage the vehicle when maneuvering in tight spaces. This is an essential skill for a trucker to learn.

Steps to Slide The Fifth Wheel on a Big Truck

The first thing to do, when getting ready to make adjustments to it’s position, is to lower the landing gear enough to take the weight and pressure from the fifth wheel and slider mechanism.This will make the adjustment easier on the truck. Yet it won’t add so much ground pressure to the landing gear, that the legs begin to lift the drives off the ground and the truck loses traction.

- The trailer brakes must be locked. This is done by flipping the slider switch on the dash of the truck. This forces the air pressure to push the pins on either side of the fifth wheel into the release position.

- Once the landing gear is lowered, the next step is to pop the pins on the slider.

- All truckers should know that it is important after flipping the switch, to get out of the truck and visually check both pins to ensure they have released properly.

- Keep these pins lubricated with a spray lubricant, to keep them sliding freely. If these pins are stuck, it can be a nightmare, to get them to release.

Related > 7 Ways to Avoid Accidents

What if the pins won’t slide?

If one of the pins does not slide out and release, gently rock the tractor back and forth to release the pressure on the pin, allowing it to slide.

- If the pin still does not release, listen for an air leak. Air pressure can pop these pins out. If there is an air leak, there probably isn’t enough pressure to allow the pin to release.

- Once both pins are out, slowly and carefully move the tractor slightly forward or back, depending on where you need to move the weight.

If you need more weight on the steering axle to get as close to the 12,000 lb allowance as possible, gently back the tractor farther underneath the trailer. - Keep a close eye on the distance between the front face of the trailer and the back of the tractor. If you are too close with the tractor to the trailer, it will destroy the swing-dip clearance. If the tractor and trailer are too close to each other, they may hit, when taking a corner or going up a driveway. Produce haulers need to take precaution when loading at produce docks. They often have a steep dip in front of the loading dock, which can cause the truck and trailer to collide when backing in. You’ll not want to explain the big dents in the back of the cab to the boss.

Related >Protect Your CDL: Driver Liability and Company Equipment

The Pins on a Fifth Wheel

The general rule of thumb is every cog on the fifth wheel slider represents 100 lb.

However, do keep in mind, every rig is different. For example, if 400 more lb. on the steering axle is needed, move the fifth wheel ahead four notches. Then reset the pins and recheck axle weights on a weigh scale. Ensure both slider pins are locked back in and the landing gear is rolled back up before heading back to the scale.

- This procedure may take a few attempts to get it right. But it will save you time and trouble at the DOT highway scales. You should enter the highway scales confident your axle weights are CORRECT EVERY TIME.

The cops are not lenient when it comes to incorrect axle weights.

Make sure as a professional driver, you know how to correctly slide the fifth wheel. It’s an important part of your job.

The first thing to do, when getting ready to make adjustments to it’s position, is to lower the landing gear enough to take the weight and pressure from the fifth wheel and slider mechanism.This will make the adjustment easier on the truck. Yet it won’t add so much ground pressure to the landing gear, that the legs begin to lift the drives off the ground and the truck loses traction.

The first thing to do, when getting ready to make adjustments to it’s position, is to lower the landing gear enough to take the weight and pressure from the fifth wheel and slider mechanism.This will make the adjustment easier on the truck. Yet it won’t add so much ground pressure to the landing gear, that the legs begin to lift the drives off the ground and the truck loses traction. If one of the pins does not slide out and release, gently rock the tractor back and forth to release the pressure on the pin, allowing it to slide.

If one of the pins does not slide out and release, gently rock the tractor back and forth to release the pressure on the pin, allowing it to slide. The general rule of thumb is every cog on the fifth wheel slider represents 100 lb.

The general rule of thumb is every cog on the fifth wheel slider represents 100 lb.